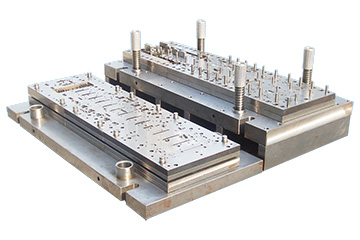

为什么我们需要冲压模具?

Why Do We Need to Have a Stamping Mold?

leading paragraph:

如果没有冲压模具,批量生产精密金属零件将很慢、成本高且不一致。冲压模具有效地解决了这个问题。

Without a stamping mold, mass-producing precise metal parts would be slow, expensive, and inconsistent. Stamping molds solve this problem efficiently.

snippet paragraph:

冲压模具对于以精度、速度和成本效益大批量生产相同的金属零件至关重要。它确保了一致性,减少了浪费,并实现了手动方法无法实现的复杂形状。

A stamping mold is essential for high-volume production of identical metal parts with precision, speed, and cost-efficiency. It ensures consistency, reduces waste, and enables complex shapes that manual methods can't achieve.

Transition Paragraph:

但是冲压模具究竟是如何提供这些好处的呢?让我们分解它以了解它在制造业中的关键作用。

But how exactly does a stamping mold deliver these benefits? Let’s break it down to understand its critical role in manufacturing.

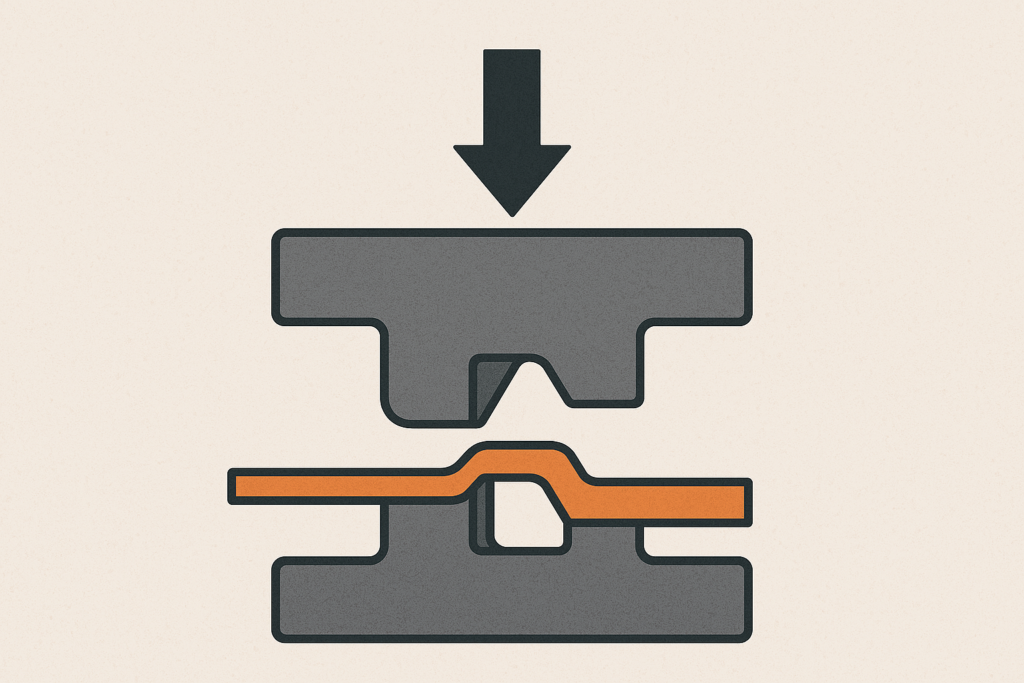

冲压模具如何提高生产效率?

How Does a Stamping Mold Improve Production Efficiency?

leading paragraph:

手动金属成型是劳动密集型的,而且容易出错。冲压模具使流程自动化,从而节省时间和成本。

Manual metal shaping is labor-intensive and error-prone. Stamping molds automate the process, slashing time and costs.

snippet paragraph:

冲压模具通过自动化零件成型实现快速生产。与手动方法相比,单个压制周期(通常为几秒钟)可创建成品零件,从而降低人工成本并将产量提高 10-100 倍。

Stamping molds enable rapid production by automating part formation. A single press cycle (often seconds) creates a finished part, reducing labor costs and boosting output by 10–100x compared to manual methods.

Dive deeper Paragraph:

冲压模具的关键效率提升

Key Efficiency Gains from Stamping Molds

| Factor | Manual Production | Stamping Mold | Advantage |

|---|---|---|---|

| Speed | 1–10 parts/hour | 500–1,000 parts/hour | 50–100x faster |

| Consistency | High variability | Near-perfect uniformity | Fewer defects |

| Labor Cost | Skilled workers required | Minimal operator input | 70–90% savings |

| Material Waste | 15–25% scrap | 2–5% scrap | Cost-effective |

关键见解 : 大批量的模具快速摊销。例如,一个 5,000 美元的模具生产 50,000 个零件,将每单位成本降低到 0.10 美元 ,而手动生产每个零件的成本为 5 美元。

Critical Insight: Molds amortize quickly for large batches. For example, a $5,000 mold producing 50,000 parts reduces per-unit cost to $0.10 vs. $5/per part manually.

哪些复杂的特征只能通过冲压模具实现?

What Complex Features Can Only Be Achieved with Stamping Molds?

leading paragraph:

某些零件的几何形状无法手动制作。冲压模具可轻松解锁复杂的设计。

Some part geometries are impossible to make manually. Stamping molds unlock intricate designs effortlessly.

snippet paragraph:

冲压模具会产生复杂的特征,如精细压花、紧密弯曲(±0.1 毫米公差)和微穿孔——这些任务使用手工工具或基本机械不切实际或不可能完成。

Stamping molds create complex features like fine embossing, tight bends (±0.1mm tolerance), and micro-perforations—tasks impractical or impossible with hand tools or basic machinery.

Dive deeper Paragraph:

冲压模具实现的高级功能<brAdvanced Capabilities Enabled by Stamping Molds

- 微精密 :

Micro-Precision:- 激光切割的模腔可实现 0.05 毫米以下的细节(例如,电触点)

Laser-cut mold cavities achieve details under 0.05mm (e.g., electrical contacts).

- 激光切割的模腔可实现 0.05 毫米以下的细节(例如,电触点)

- 多步骤表单 :

Multi-Step Forms:- 级进模在一个周期内进行切割、弯曲和压印(例如,汽车支架)。

Progressive dies perform cutting, bending, and coining in one cycle (e.g., automotive brackets).

- 级进模在一个周期内进行切割、弯曲和压印(例如,汽车支架)。

- 材料灵活性 :

Material Flexibility:- 适用于不锈钢、铝,甚至回火合金 (HRC 40+)

Works with stainless steel, aluminum, and even tempered alloys (HRC 40+).

- 适用于不锈钢、铝,甚至回火合金 (HRC 40+)

真实示例 :智能手机 SIM 卡托架需要 0.2 毫米厚的不锈钢和精确的切口——只有使用精密模具才可行。

Real-World Example: Smartphone SIM trays require 0.2mm-thick stainless steel with exact cutouts—only feasible with precision molds.

总结

Conclusion

冲压模具对于快速、精确和经济高效地批量生产金属零件是必不可少的,可实现手动方法无法实现的复杂性。

Stamping molds are indispensable for fast, precise, and cost-effective mass production of metal parts, enabling complexities unattainable by manual methods.